Welding Electrode/ Rod/ Pre-heat/ SAW Flux/ FCAW/ TIG ovens

Why use Smithweld, Australian made, quality Welding Electrode/ Rod ovens.

Industrial welding electrode/ rod ovens are necessary to control/remove moisture that may be present in the electrode coating for the Manual Metal Arc Welding process (MMAW), reducing the risk of weld failure. Smithweld Ovens are specially designed to ensure that any moisture that may be present in the electrode (rod) is removed. The baking/conditioning and long-term storage process also applies to SAW-Flux, FCAW & TIG welding wires as well.

We have digital control options on all our ovens from S-12F and up. All models with digital control units have single point calibration included as standard, with mounted temp gauge calibration and re-calibration available as optional extras. If you have any specific requirements outside of our standard products, please (contact us) as we are able to customize to meet your needs.

Choose your oven wisely

Smithweld have been designing & manufacturing ovens for over 25 years, we pride ourselves on our oven quality and durability. Our ovens are also thermally efficient due to the quality of our insulation and patented oven door seals, which reduces operating costs.

There are many welding ovens on the market, only Smithweld ovens have been built to the superior quality necessary to service the oil, gas and mining industries. Don’t risk using inferior built ovens, Smithweld ovens will still be performing long after the alternatives have failed. Cost blow-out and delays to your project due to plant failure are avoidable, buy Smithweld products. Smithweld Ovens are the most reliable on the market.

Temperature Calibration

As of October 2012, Smithweld includes a single point “calibration certificate” with all their digital ovens, optional single point calibration on mounted temp gauges and a “certificate of compliance” for all ovens purchased. The potential for electrode ovens to eventually vary from their true readings is especially high in mining and heavy industrial environments. As such industrial ovens need to be re-calibrated at regular intervals to maintain QA requirements.

Smithweld ovens exceed compliance with AS/NZS-3000-2009 electrical standards.

Showing 1–12 of 13 results

-

S-1000HD Digitally Controlled, High Temperature Large Capacity Pre-heat Oven

-

S-120F SAW Flux Heating Oven

-

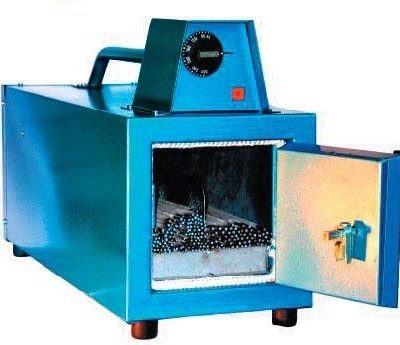

S-12F 14 Kg Portable Rod Oven

-

S-12FD 14 Kg Digitally Controlled Portable Rod Oven

-

S-150H High Temperature Rod/Pre-heat Oven

-

S-150HD Digitally Controlled, High Temperature Rod/Pre-heat Oven

-

S-150M Mid-Temperature Rod/Pre-heat Oven

-

S-150MD Digitally Controlled Mid-Temperature Rod/Pre-heat Oven

-

S-200 Series – (E, E-W, W) Mid Temperature Rod/Pre-heat Oven

-

S-400FCLT Low Temperature, Bulk Wire/Electrode Pre-heat Oven

-

S-5ELV-32V The extra low voltage 5Kg Portable Electrode oven

-

S-5F 5 Kg Portable Rod Oven